About Demagnetizer

Total Soution for Demagnetization

Holding Electric is the leading demagnetizer manufacturer in Taiwan. We have nearly 40-year experience in designing and manufacturing demagnetizers. We have developed more than 20 kinds of reliable and stable demagnetizers to provide a full range of professional solutions for your demagnetization needs.

Our demagnetizer has been widely adopted in the industry, including the following demagnetizing applications.

* Raw materials such as steel rods, steel pipes, steel plates, etc.

* Machine components such as spindles, bearings, gears, slide rails, & molds.

* Precision parts such as aerospace, semiconductor, 3C, automotive, & medical parts.

* General hardware, screws, fasteners, and hand tools.

* Demagnetization in the factory, such as sheds, frames, or conveyors.

How Demagnetizer Works

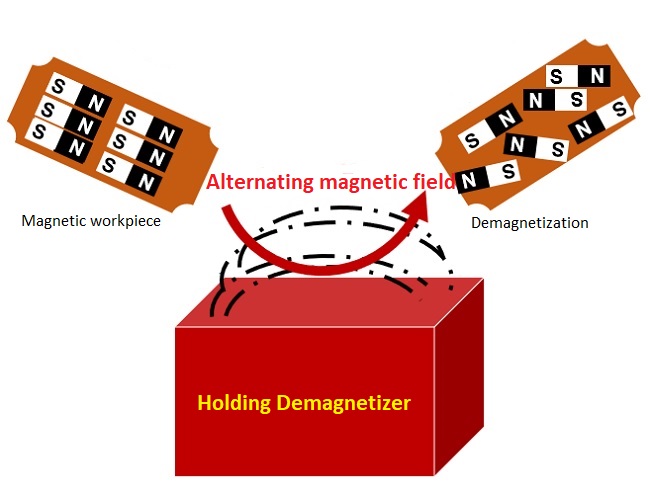

The demagnetizer is composed of multiple sets of specially designed coils. The purpose of these coils is to project the largest magnetic field in the target demagnetization area. When AC power is applied, an alternating magnetic field that changes dozens of times in one second is generated in the demagnetization area. When the workpiece enters the demagnetization zone, the magnetic domain direction in the workpiece will be rapidly changed by the influence of the alternating magnetic field.

Please note that to complete demagnetization, the workpiece must be moved in and away from the demagnetization area! In this way, the directions of the magnetic domains in the workpiece will be completely disrupted because the time of leaving the magnetic field is different.

An Introduction on

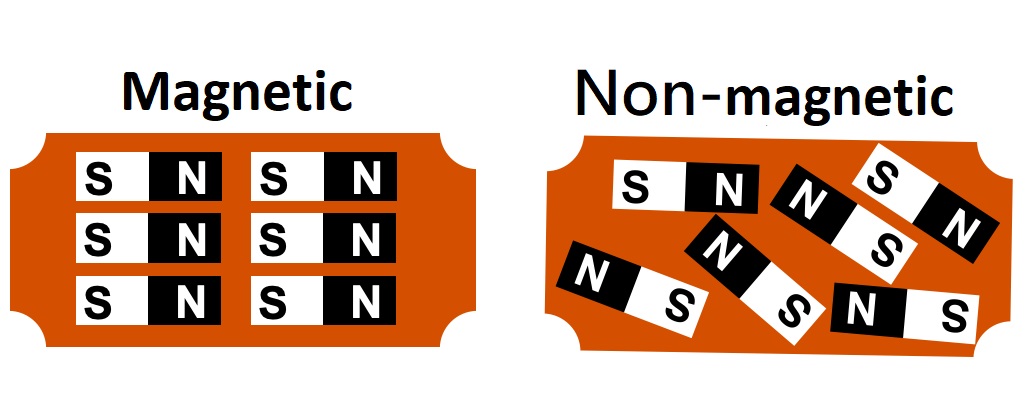

Many metals such as iron and nickel have magnetism. Many people think that magnetism is like heat. Injecting magnetic energy into a metal can cause the metal to be magnetic, and demagnetizing means extracting the magnetic energy from the metal. Actually, this is a wrong concept. Inside magnetic metals, there are many small blocks called "magnetic domains." Each magnetic domain carries magnetic properties, and this magnetic property cannot be eliminated.

So why can we magnetize or demagnetize a piece of iron?

In fact, the magnetism we see in daily life is a macro effect produced by aligning magnetic domains in the same direction. In other words, when the magnetic poles of all the magnetic domains point in the same direction, the magnetic properties of the magnetic domains will accumulates and generating a magnetic force from a marco perspective.

Conversely, if the pole directions of the magnetic domains are disturbed, the magnetic force of the magnetic domains cancel out each other. From a macro perspective, there is no magnetic force.

Causes of Residual Magnetic Force

Why would a non-magnetic workpiece be magnetized? In industry, there are several reasons.

- Magnetic tools:

The magnetic tools has many applications in the industry, and the side effect is that it will magnetize the workpiece. For example, when using magnetic spreaders and fixtures to carry or fix a workpiece, residual magnetic force will be generated after releasing. - Machining or Heating Process:

Heating, squeezing, stretching, or even rubbing a steel may changing the arrangement of internal magnetic domains and therefore magnetizing the workpiece. - Magnetic pollution:

Magnetic force are "contagious". If there are magnetized item nearby, or the storage such as the racks or conveyor are magnetized, the non-magnetic parts may be contaminated and become magnetic.

Side Effects of Residual Magnetic Force

Residual magnetic force has many side effects.

- Actuation parts such as gears or bearings could draw iron filings, which will increase resistance and reduce part lifetime.

- Cutting tools or the workpiece could draw iron filings, which will affect the machining accuracy and reduces tool lifetime.

- Screws or fasteners draw iron filings making it difficult to assembly.

- Oil and water pipe parts draw iron filings, which will affect the circulation.

- The workpieces are sticky to each other and difficult to separate them.

- When welding, the residual magnetic force will make the arc shift.

- When electroplating, the residual magnetic force will result in current deviation and affect the plating effect.

- Affects the reading of the sensor or compass, which is especially severe in Industry 4.0 applications.

(Iron filings drawed by the workpiece and affect subsequent processing)

In recent years, due to the continuous enhencement of precision in the industries, the requirements for demagnetization have also increased. From raw steel materials, machine elements, precision parts to even general hardware, we can see strict regulation on residual magnetic force everywhere.