RFID for Smart Tool Management Chip

•Industrial-grade RFID Chip

•The size of the chips conform to DIN69873.

•The communication of the chips conform to international standards, ISO15693/ISO14443A.

•operating in the HF frequency band (13.56MHz).

•With a unique identification code (UID), it can store a large amount of data

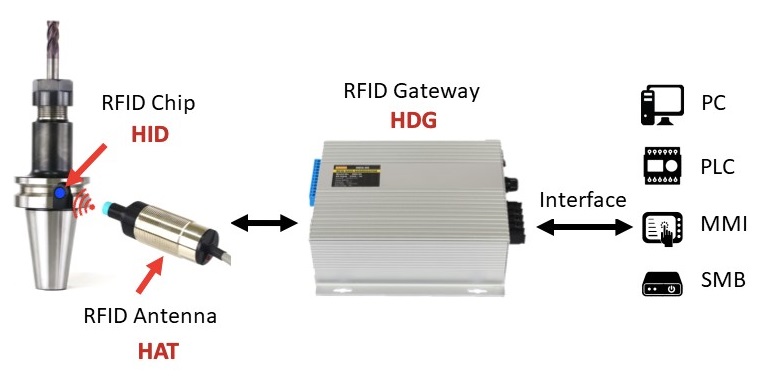

Developed by Holding, the domestic industrial-grade RFID system is suitable for industrial IoT applications such as smart tool or mold management.ID Code gives tools the ability of memory. By implanting a small tag on the tool holder, users can store a large amount of data into the tool holder and access it by an HMI (human-machine interface).

This system can be used in various smart industry scenarios, including tool ID management, dimension and offset management, lifetime management, and information management.

It is designed and manufactured in Taiwan with competitive price and provides complete and flexible technical support

RFID Chip – HID:The data carrier to be mounted on the tool. In line with ISO international standards.

If it is inserted into the standard chip hole of the tool, each tool can be given a globally unique id code. Important information such as length, diameter, tool holder position, and tool number can be accessed at any time.

RFID Gateway – HDG:For advanced users with system integration needs. Allowing third-party PLCs to directly accesses the tag.

RFID Antenna – HAT:For accessing the HID. With fixed screw, it can be installed in the machine to facilitate automatic R/Wand HID.